|

|

|

|

Ceramic Honeycombs>>RTO Ceramic Honeycombs Sales: Biz@jintai-group.cn

Heat Transfer Media for RTO

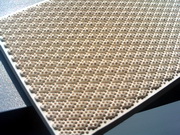

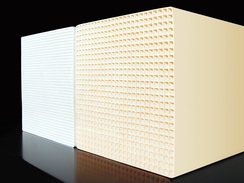

Ceramic Honeycombs for RTO

Product No: (JT-CH-RTO)

Introduction of JINTAI Regenerative Thermal Oxidiser Ceramic Honeycombs:

Regenerative Thermal Oxidizers are used to destroy Hazardous Air Pollutants (HAPs), Volatile Organic Compounds (VOCs) and odorous emissions that are often discharged from industrial processes. The RTO achieves emission destruction through the process of high temperature thermal or catalytic oxidation, converting the pollutants to carbon dioxide and water vapor while reusing the thermal energy generated to reduce operating costs. RTO Units use two primary medias: JINTAI Ceramic Honeycomb Monoliths and Ceramic Saddles. Each of these products offers excellent heat capacity, thermal shock, and chemical resistance properties for use in RTO units. Ceramic Honeycomb Monoliths are specified as structured RTO media and Ceramic Saddles are a form of random RTO media.

Ceramic Honeycomb Materials: Cordierite, Porcelain, Mullite, Alumina, Stoneware, etc.

Dimension and Physical Properties:

|

Dimension |

Quantity |

Wall |

Channel |

Surface |

Void

Section(%) |

|

150×150×300 |

25×25 |

1.0 |

4.96 |

580 |

68 |

|

150×150×300 |

32×32 |

1.0 |

3.66 |

695 |

61 |

|

150×150×300 |

40×40 |

0.7 |

3.03 |

891 |

65 |

|

150×150×300 |

43×43 |

0.7 |

2.77 |

940 |

63 |

|

150×150×300 |

50×50 |

0.6 |

2.39 |

1090 |

63 |

|

150×150×300 |

60×60 |

0.5 |

1.99 |

1303 |

63 |

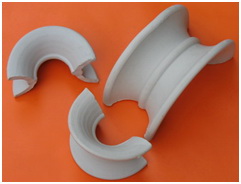

Ceramic Saddle for RTO

Product No: (JT-CS)

Ceramic Saddles are mostly used as heat transfer media and are of much higher density and require good high temperature resistance, which are made from chemical porcelain and have excellent resistance to acids except in the case of hydrofluoric acid. Moisture absorption must be less than half a percent.

Ceramic Saddles Features: excellent resistance to abrasion, high mechanical strength, excellent resistance to thermal shock, consistent packing factors.

Chemical Composition:

|

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

<0.5% |

Other |

|

>73% |

17-25% |

<1.0% |

<0.5% |

<0.5% |

2-4% |

<0.1% |

Size Available: 3/8”, 1/2”, 5/8”, 3/4”, 1”, 1.5”, 2”, 3”

-Ceramic Foam Filter-

Alumina Ceramic Foam Filter

SiC Ceramic Foam Filter

Zirconia Ceramic Foam Filter

-Tower Packing-

Ceramic Random Packing

Metal Random Packing

Plastic Random Packing

Structured Packing

-Ceramic Honeycombs-

Infrared Ceramic Tile

Ceramic Honeycomb Substrate

RTO Honeycomb Ceramic

Diesel Particulate Filter

Honeycomb Foundry Filter

-Others-

Chromium Metal

Alloying Tablets

Titanium Sponge

Molecular Sieves

Acid Resistant Ceramic

Inert Alumina Ceramic Balls

-Product Navigation-

Product Photo Gallery

Product Application

Copy Right © 2005 Jiangxi Jintai Special Material LLC. All Rights Reserved

E-Mail: biz@jintai-group.cn Web: www.ceramic-honeycombs.com

Address: Room1008, Heng Long International Building, No.93 Yue Jin South Road, PingXiang, JiangXi 337000, China